Pin Gauges vs. Slicing Gauges

Steve Latta compares two types of marking tools used to scribe lines for joinery.

Pin gauges and slicing gauges fall under the umbrella of marking gauges and are primarily used to scribe lines for joinery.

Pin gauges are simple and inexpensive. They consist of a steel pin mounted near the end of a bar that’s most often made of wood. Without refinement, the pin makes a V-shaped cut that tends to rip the fibers when marking across the grain, as for a tenon.

The bane of the pin. Marking across the grain with a pin gauge leads to torn wood fibers and a ragged cutting line.

On slicing gauges (often called cutting gauges), the pin is replaced by a knifelike cutter that typically is flat on the outside face and beveled on the inside. This wedge shape pulls the main body of the gauge tight to the edge of the stock and discourages the blade from wandering. This profile also leads to tighter joinery because the bevel is on the waste side of the cut.

Clean cutting. The knife gauge makes clean cross-grain marks and its square fence offers a good bearing surface.

A modern variation of the slicing gauge is the wheel gauge, which uses a beveled circular cutter mounted at the end of a bar or a round steel shaft. The cutter does not rotate during use. When a section of its edge dulls, it can be loosened and rotated to expose a new section.

Little bearing surface. The wheel gauge makes clean cross-grain cuts, but the disk-shaped fence provides little support for marking.

The all-metal versions of the wheel gauge come with disk-shaped fences that typically are smaller than the rectangular wood fences common to traditional slicing gauges. To me, they feel awkward and provide too little bearing surface along the edge of the workpiece. Still, many folks I know would be reluctant to give theirs up.

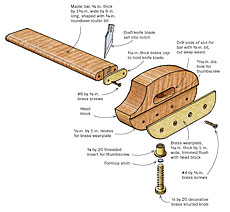

Latta’s own. Shopmade slicing gauge from Question and Answer department of FWW #189.

I prefer a shopmade slicing gauge (mine is shown in FWW #183, p. 46). Commercially made slicing gauges with wide fences include traditional Western designs (for example, by Crown Tools) and Japanese versions, which have especially large fences.

If you have a pin gauge, you can convert it to a slicing gauge. Just file the pin’s outside face flat and its inside face on an angle to form an edge that actually will cut the wood.

From Fine Woodworking #193

Photos: Charlie Reina

Log in or create an account to post a comment.

Sign up Log in