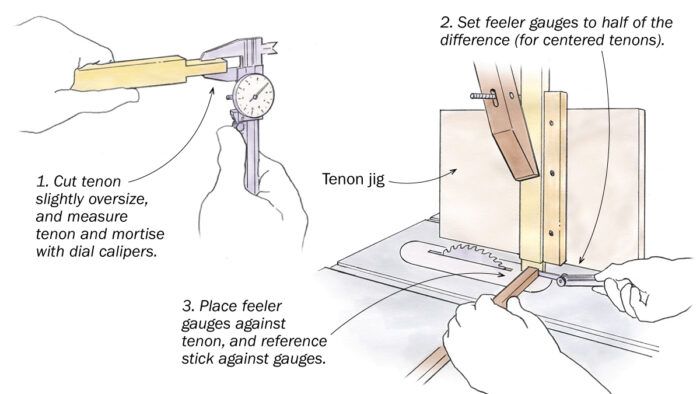

Use feeler gauges to dial in your tenoning jig

Team up your dial calipers with a set of feeler gauges to sneak up on the perfect tenon size.

I cut tenons on the table saw, using a jig that stands the pieces on end. I’ve always fit the tenon to the mortise by gradually adjusting the jig to sneak up on the perfect tenon. It occurred to me that I could save time and improve accuracy by teaming up my dial calipers with a set of feeler gauges.

I start by cutting the tenon slightly oversize. Then I use the calipers to compare the tenon thickness with the mortise width. If you are making cuts on both sides of a centered tenon, you’ll need to divide that difference in half. If you’ve got one cheek already cut accurately, you can remove the full difference. Whatever the number is, select a combination of feeler gauges that matches it. With the workpiece in the jig, place the feeler gauges against the tenon, and bump a reference piece up against the other side of the feeler gauges. Hold the reference piece right there, take away the feeler gauges, and adjust the jig until the tenon cheek is resting against the reference. You’re ready to cut the tenon to final size, and all of the other tenons in your assembly as well, with 0.001-in. accuracy.

—BOB RIFKIN, Acton, Mass.

Illustrations by Dan Thornton

From Fine Woodworking issue #308

Log in or create an account to post a comment.

Sign up Log in