Tune up an all-purpose hatchet into a carving axe

Andrea Cortés provides an accessible tooling alternative to start spoon carving.

As a spoon carving teacher, it hasn’t been easy to find an affordable but good carving axe, at least here in Spain.

When I was starting out, I was lucky to be able to get a Gransförs Large Carving Axe, (which I later regretted, and I will tell you why in a bit) but most of my students are looking to carve spoons as a hobby and don’t really want to invest a lot.

The good news is you do not need an expensive carving axe; you can tune up an all-purpose hatchet into a perfectly good carving axe to get started.

It really all comes down to three basic things: size, weight, and edge geometry.

Weight

A carving axe needs to be light enough so we can carve for a while and not get fatigued, also heavy enough so the chopping action is efficient thanks to weight of the head but still allows us to have good aim.

For me, the sweet spot is around 650 grams (1.5 lb.). That’s why I regretted buying the Gransförs, which was way too heavy and ended up injuring my wrist. I know plenty of carvers, bigger than me, for whom the Gransförs is perfect. After all, Gransförs is from Sweden and I’m a tiny Colombian who’s probably the same height as an average 12-year old Swede.

Size

Size wise, most all-purpose hatchets you find in hardware or home improvement stores are appropriate for carving, with handle lengths around 30-40cm and heads between 400-800 grams.

When we find one that feels comfortable and the correct weight for us, we just need to grind the correct edge geometry for carving.

Edge geometry

Most hatchets come with a bullet-shaped edge meant for splitting firewood and chopping that doesn’t require much precision. For carving, we need wide bevels, ideally flat so we can slide on the wood and actually engage the edge.

The first thing we need to do is grind off the convexity and set two symmetrical bevels.

Widening the bevels

The wider the bevels, the easier it will be to engage the edge in a very controlled way, which is great for along-the-grain action but not so much for chopping because the edge would be too fragile. So we need to find a balance which will depend also on the thickness of the axe head.

For the type of axe I’m working with, bevels of 9-10mm (around ⅜ in.) work best.

I use a permanent marker to draw the width of the bevel, which will help establish the correct angle on the grinding wheel by aiming to the middle.

I use a fast grinding wheel first to remove steel as fast as possible and then move on to a slower, water-cooled sharpening system which also allows more control of the angle to get perfectly even hollow-ground bevels.

It’s important to feel a burr all along the edge when we finish grinding each side.

Filing down

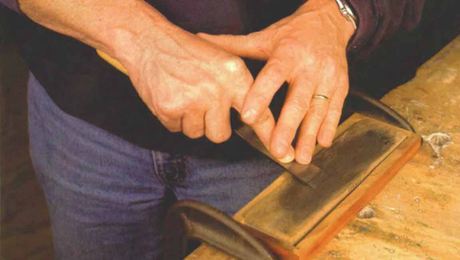

Now we can move on to creating a flat bevel using diamond files or regular sanding paper on a scrap wood block. It’s important to use a progression of grits that allows us to erase the tracks from the previous one until we get a polished surface.

Being very careful, position the file on the bevel, making sure it is registering the edges of the concavity, and slide the file along the edge until there is visible scratch pattern of the same width and there is a slight burr on the other side. Repeat on each side using all the grits.

The hollow-ground edge can feel very bitey but as we use the axe and continue to sharpen it, the bevels will become flat and this will change the way the edge engages the wood. You can adjust this to your liking by sharpening completely hollow with a thin micro bevel or going for the full flat bevel.

We have now a perfectly good carving axe to get started with. As an extra step, we can re-shape the handle to make it look better. I like stripping off the glossy finish using a card scraper and creating small facets for a nicer grip. Apply some natural oil for protection and enjoy!

|

Video: Axes and adzes for bowl carvingGreen woodworker Dave Fisher shows you exactly what he looks for in his go-to carving tools for making chips fly. |

|

The simple art of spoon carvingWindsor chairmaker Peter Galbert blows off steam by picking up a carving knife and whittling spoons. |

|

From the archive: Carving tool tune-upWith keenly honed tools, you’ll sharpen your skills as a carver. |

Log in or create an account to post a comment.

Sign up Log in