Tool Test: Router Tables

The best offer flat tables, versatile fences, and good dust collection

Synopsis: Mounted in a table, a router can spin out perfect sliding dovetails, and tenons that fit their mortises straight from the table. You can also rout more consistent edge profiles using a router in a table rather than a handheld version. And although many woodworkers make their own router tables, there’s an argument to be made for buying a manufactured one. Accuracy, convenience, easy adjustability, and the fact that you can add a router lift are just a few of the advantages. We tested manufactured router tables, checking them for all of the above and more.

Models tested include: Excalibur 40-200C, JessEm Mast-R-Top with Rout-R-Fence and Rout-R-Stand, Bench Dog Cast-Iron router table with steel cabinet, Excalibur 40-200P, JessEm Mast-R-Top with Mast-R-Fence II and Rout-R-stand, JessEm Mast-R-Lift Excel II, Rockler Pro Phenolic table with steel stand, Woodhaven 8243K, Festool CMS GE Basic, Sommerfeld Tools router table.

There seems to be no limit to what the router can do. That’s why just about every woodworker has one. But if you are using the router only as a handheld tool, you’re not taking full advantage of its versatility. Mounted in a table, the router becomes a super-accurate joinery machine that can spin out perfect sliding dovetails, and tenons that fit their mortises straight from the table. You can also rout more consistent edge profiles because the router won’t tip.

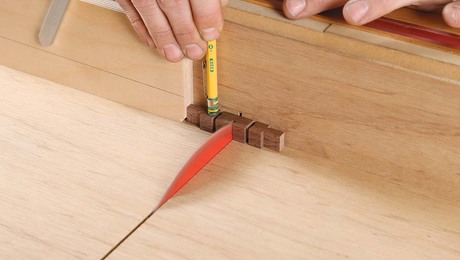

It’s not hard to make a router table in your shop. All you need is a piece of plywood or MDF for the top and a straight piece of wood for the fence. Bolt the router to the top and you’re good to go. But there are problems with shopmade tables. If you go the simplest route and bolt a fixed-base router to the table, you’re stuck reaching underneath to adjust the bit height, and removing the router altogether to change bits. Even using a router with above-the-table adjustments, you probably won’t be able to change the bit that way because the table will be too thick to allow the collet to get above it. And a simple fence will be hard to adjust.

So, if you are looking for a new router table, it makes sense to get a manufactured one. You’ll get a smooth, durable top, a rigid fence that’s easy to adjust, and built-in dust collection. The top will also accommodate a router lift, which makes it a snap to change bits and bit height from above the table. Add one of those (see p. 46) and a powerful router, and you have a tool that adjusts like a shaper, setting up precisely for any task in just a minute or two.

With this in mind, the editors at Fine Woodworking asked me to review the manufactured router tables currently available. For accurate work, the table’s flatness is critical. So I eliminated tops with MDF cores, because past testing has shown that they are more prone to sagging. That left only tables made from cast iron, solid phenolic, and aluminum.

For the full article, download the PDF below:

Comments

I use the Kreg Precision Router System with a Jessem Rout-R-Lift II and a Hitachi 2-1/4 HP Router. I am very happy with the whole system. I've had one problem. I bought a Bosch 2-1/4 HP router that I wanted to put in the lift. This is so I could use the Hitachi in its plunge base. Unfortunately, the Bosch motor is just a bit too big to fit in the lift. It still works out. I'll buy another router that I will verify can fit in the lift. I write all this is because the Kreg system is not included in this review.

Log in or create an account to post a comment.

Sign up Log in