Sharpening Turning Tools

If you want to turn spindles successfully, you need to start with sharp turning tools.

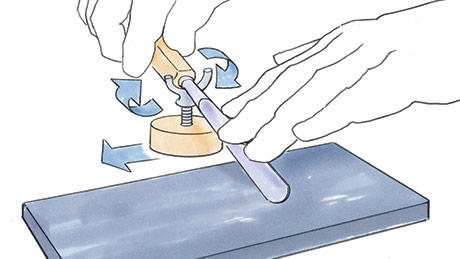

The first step to mastering any woodworking skill is to start with the right tools, and as usual, the best tool to start with is a sharp one. Professional furniture maker and instructor David Douyard starts his sharpening process at the slow-speed grinder, equipped with a Wolverine jig. While not absolutely necessary, the Wolverine jig makes grinding primary bevels quick and easy—and more importantly, repeatable. From there, David uses diamond paddles or his sharpening stones to create a micro-bevel on the very edge of the chisel or gouge.

Videos in the Series

-

Sharpening Turning ToolsApril 2, 2019

-

Turning for Furniture Makers: The Roughing GougeApril 9, 2019

-

Turning For Furniture Makers: Roughing from a riven blankApril 16, 2019

-

Turning For Furniture Makers: The Skew ChiselApril 23, 2019

-

Turning For Furniture Makers: V-Grooves and BeadsApril 30, 2019

-

Turning For Furniture Makers: Accurately Sizing Parts and TenonsMay 7, 2019

-

Turning For Furniture Makers: Turn a carving mallet – ConslusionMay 14, 2019

Comments

Great video. David is a terrific teacher, very clear, concise and calm. Looking forward to more of these videos with him.

I was waiting for how to sharpen a spindle gouge but it didn't happen. Coming later?

Super video. Having both a Wolverine grinder setup and Tormek it convinces me that the Wolverine grinder setup is perfect tool to use with my Jet 14 inch lathe. No need to take the sharpening to a razor edge for each turning event. Small comments within the video are priceless.

A thought that occurred to me as I watched this. People often ask why turners sharpen so often; while bowl turning is a slightly different beast, the math works the same. When turning a 10” bowl at 1000 rpm the tool is taking a shaving that’s nearly six miles long every minute its in contact with the wood.

Sharp tools don’t stay sharp long. Learn to sharpen first, sharpen often.

Good video, good information.

Turner1029, you make a really good point and this is a fantastic illustration regarding sharpening of lathe tools. However, are you sure it’s not 0.496 miles per minute vs nearly 6 miles? I could be wrong here, really trying to understand if I am off. 10 inch diameter is 31.4 inch circumference x 1,000 rpm = 31,400 inches per minute. 63,360 inches in a mile if internet-site conversion calculators can be trusted. Even if this is right vs the 6 miles, half a mile is big for an edge tool.

user-6001446

You're absolutely right. 10/12 of a foot diameter. Mult by pi. 2.617 feet per rev. Mult by 1000 is 2617 feet per minute. 5280 feet in a statute mile when I went to school. So... 0.496 miles per minute. Nuttin' wrong with the imperial system. The metric system is for the "mathematically challenged".

Log in or create an account to post a comment.

Sign up Log in