Synopsis: Paul Anthony, author of Taunton’s Complete Illustrated Guide to Tablesaws, gives a step-by-step guide to making accurate, safe ripcuts on the tablesaw. From making sure your fence and splitter are aligned properly, to safe solutions for straightening a crooked edge, to the proper procedure for ripping wide panels, Anthony’s guidelines will ensure safer tablesaw cuts with less chance of dangerous kickback.

From Fine Woodworking #206

The tablesaw is a wonderful tool for cutting parts to size, and ripping is its most common task. “Ripping” means sawing wood parallel to its grain—usually when cutting boards to narrower widths. You can do the job with a bandsaw or a portable circular saw, but a tablesaw is much more efficient. It is powerful, and the rip fence allows you to cut identical multiples. The large surface also makes handling stock of all sizes much easier.

This article will tell you how to safely and accurately use the tablesaw to rip solid lumber as well as sheet stock.

To do the work safely, you need to follow the proper steps and use the right accessories, including—most importantly—a splitter. A riving knife is a more sophisticated splitter, and works even better.

Prep the saw: Most tablesaw accidents result from violent kickback during ripping, but a properly aligned splitter will prevent kickback by keeping the workpiece from contacting the rising rear teeth of the blade and being thrown back at you. Also, when possible, use a blade guard to prevent hand-to-blade contact and keep sawdust out of your face.

Safety and quality of cut also depend greatly on a straight fence that’s set parallel to the blade. Even a premium fence goes out of alignment after a while, so make sure to check it for parallel occasionally by measuring from the blade to the locked fence at both the front and the rear of the blade. Some woodworkers cock the outfeed end of the fence away from the blade by 1⁄32 in. or so, which is fine.

Finally, an outfeed table is an absolute necessity, even when ripping short pieces. Without one, your work just falls to the floor, possibly damaging edges and corners. Outfeed support is critical when ripping long stock, which may otherwise start to tip off the saw table before the cut is complete, forcing you to bear down on the trailing end of the board right at the spinning blade.

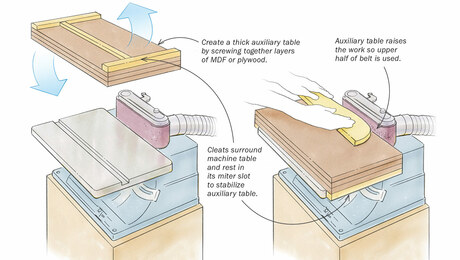

You might also want to set up infeed support, especially for long, heavy boards or sheet goods.

Prep the stock: To rip safely, the edge that contacts the rip fence must be straight, and the face that bears against the table should be flat. That way, the board doesn’t pinch against the blade or rock as you’re feeding it.

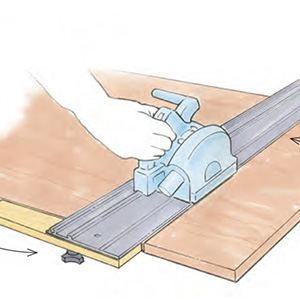

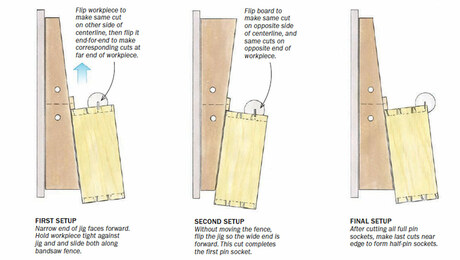

So the first step is to create a straight edge. If the edge is already reasonably straight, the quickest approach is to run it across the jointer. If the edge is severely crooked or is a waney, “live” edge, you’ll need to saw it.

For the full article, download the PDF below:

Log in or create an account to post a comment.

Sign up Log in