Make Your Own Dowels

With a dowel plate, you can customize the size and species to make stronger, prettier pegs.

Synopsis: Pegged mortise-and-tenons are a staple of Arts and Crafts furniture, and since Michael Pekovich loves the style, he pegs a lot of joints. Store-bought dowels are fine, but they come in a limited number of species. Making your own offers more versatility and it’s easy if you follow a few tips. Start with straight-grain stock, ease the corners using a V-groove jig, sharpen the ends to a blunt cone, and use a dowel plate to form them. Pekovich also provides techniques for foolproof installation, whether you plan to cut the pegs flush or set them proud of the surface.

Because the furniture I make is heavily influenced by the Arts and Crafts movement, I cut a lot of mortise-and-tenons, and peg the joinery to add strength and visual pop. I’m always in need of dowel stock to make the pegs. Store-bought dowels are fine, but they come in only a few species, and if you don’t have what you need on hand, work stops until you get it. That’s why I began making my own. With a dowel plate, it’s a snap to bang out a few dowels whenever I need them, in whatever species I choose.

Making a dowel might seem simple: Pound a stick through a hole. But there are a few potential pitfalls— broken pegs being the worst. Through the years, I’ve learned some tricks that help you to avoid these headaches. I’ll show you my techniques so that you, too, can end up with nicely formed dowels.

Places for pegs

Sure, a joint reinforced by a peg is stronger than the same joint without one, but that’s not the only reason to peg joinery. Even when made from the same wood as the joint, there’s just enough contrast from the end grain to sound a quiet decorative note.

Making a dowel

Use straight-grain stock

Runout—grain that flows out to a board’s edge—in the blank causes it to split when you pound it through the dowel plate or, even worse, when you’re driving the peg into the joint. Resaw the peg blank so you get stock with straight grain. The blank should be as close to the dowel’s final diameter as possible.

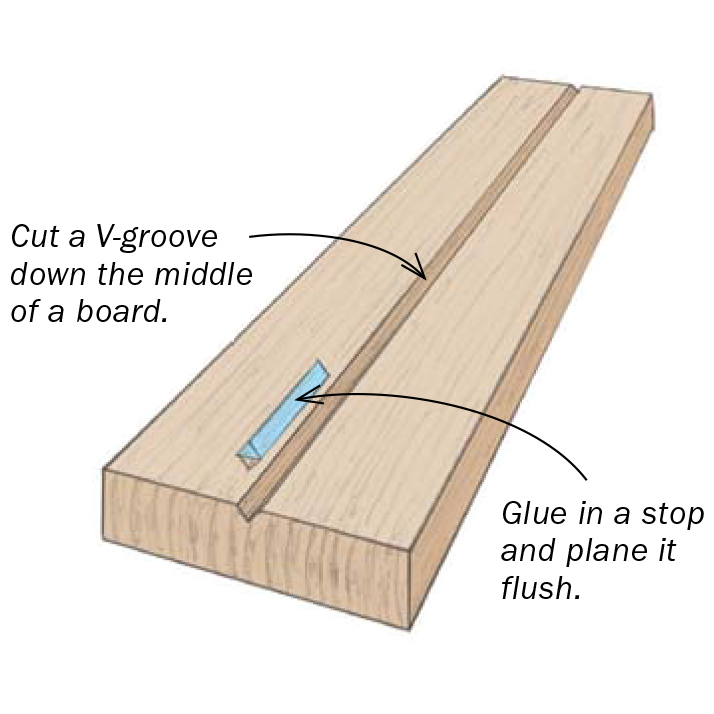

Ease the corners

The sharp corners of a square blank get rolled up and jam when the blank is driven through the plate’s round hole. To prevent this, chamfer the corners with a block plane first. A jig holds the small stock for planing.

From Fine Woodworking #248

From Fine Woodworking #248

For the full article, download the PDF below:

Log in or create an account to post a comment.

Sign up Log in