James Krenov’s dowel joint

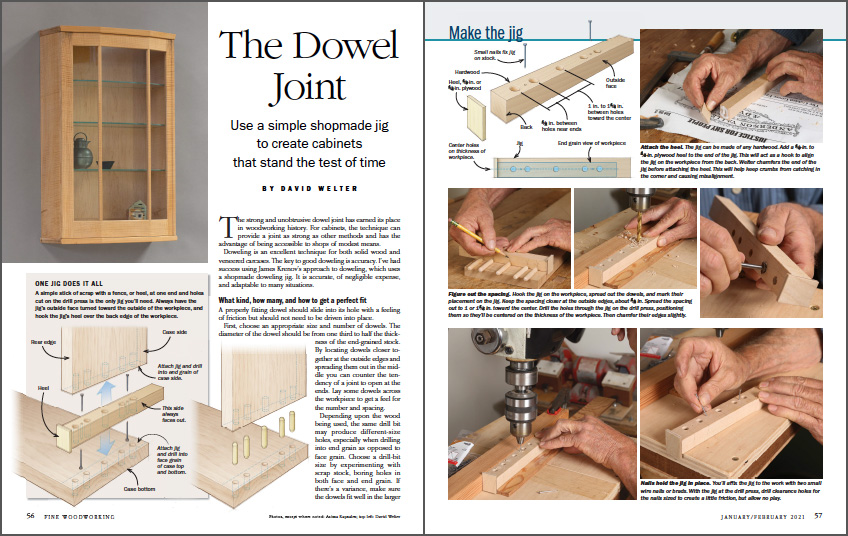

Use a simple shopmade doweling jig to create cabinets that stand the test of time.

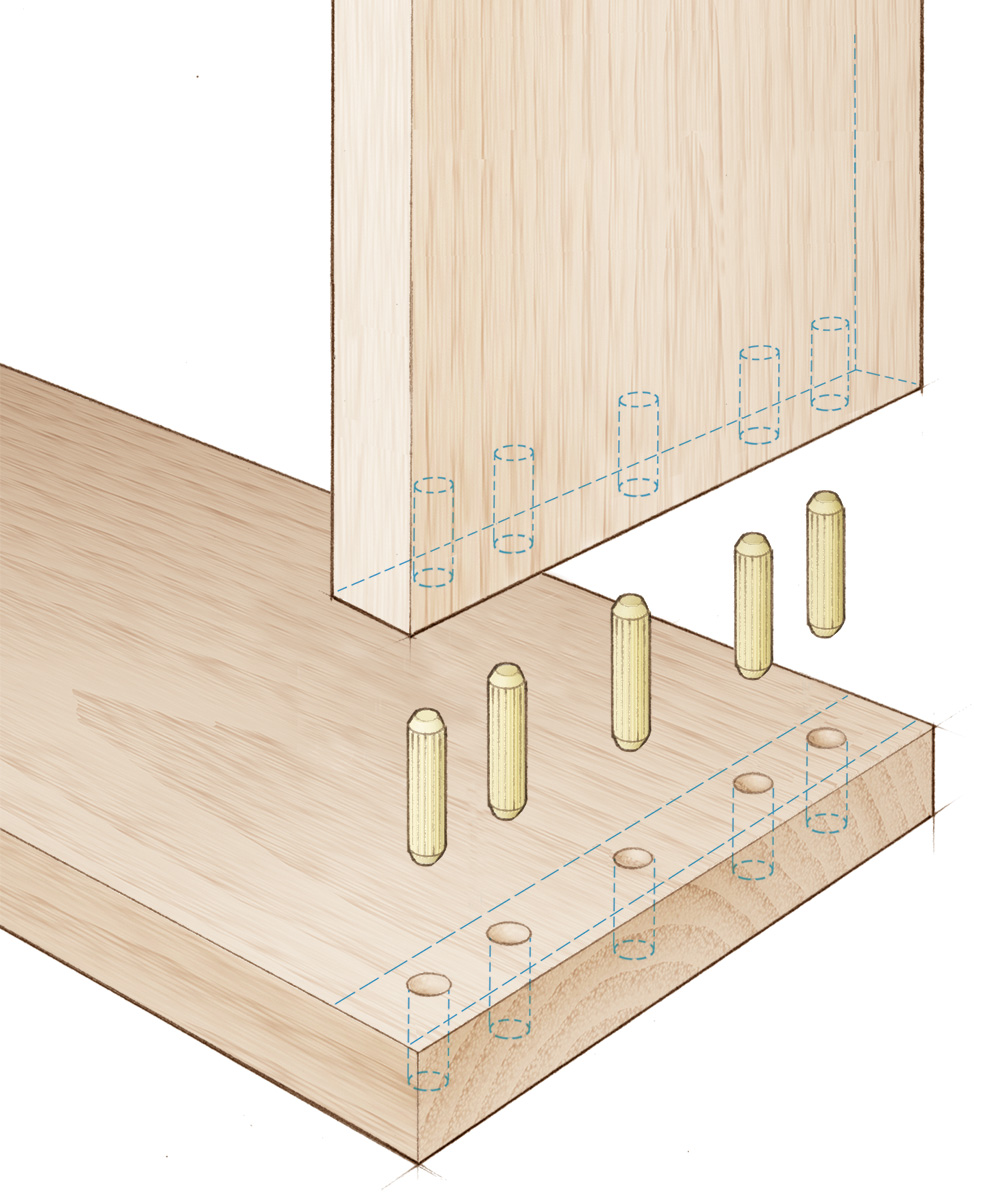

Synopsis: Doweling is a great joinery technique for both veneered and solid-wood carcases. It creates a strong joint and is accessible to most any woodworker. The key is accuracy. David Welter uses the doweling technique he learned from James Krenov. One simple jig takes care of all the layout and ensures all the holes drilled are accurate.

The strong and unobtrusive dowel joint has earned its place in woodworking history. For cabinets, the technique can provide a joint as strong as other methods and has the advantage of being accessible to shops of modest means.

Doweling is an excellent technique for both solid wood and veneered carcases. The key to good doweling is accuracy. I’ve had success using James Krenov’s approach to doweling, which uses a shopmade doweling jig. It is accurate, of negligible expense, and adaptable to many situations.

What kind, how many, and how to get a perfect fit

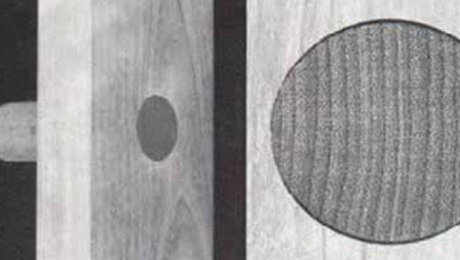

A properly fitting dowel should slide into its hole with a feeling of friction but should not need to be driven into place.

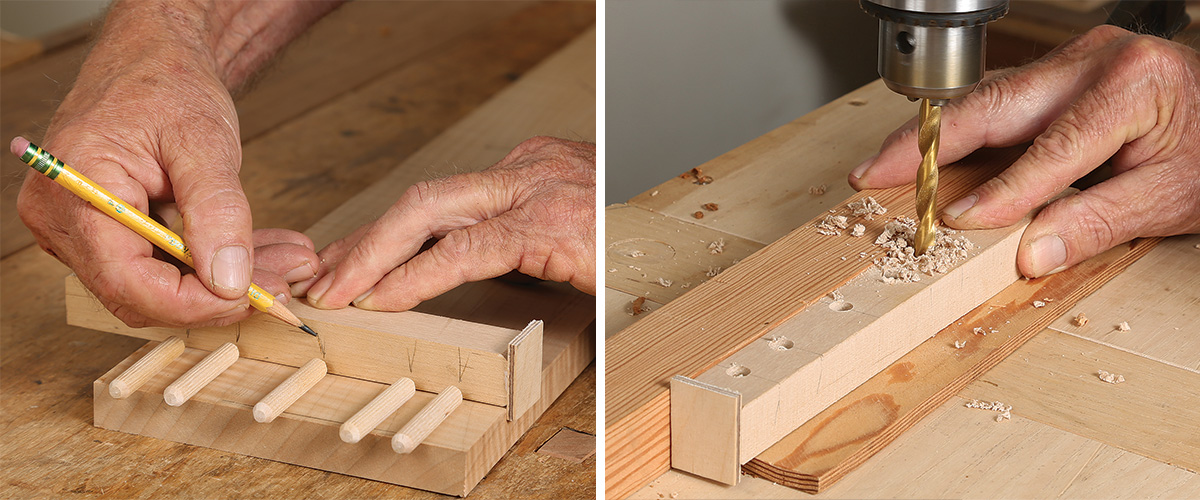

First, choose an appropriate size and number of dowels. The diameter of the dowel should be from one third to half the thickness of the end-grained stock. By locating dowels closer together at the outside edges and spreading them out in the middle you can counter the tendency of a joint to open at the ends. Lay some dowels across the workpiece to get a feel for the number and spacing.

Depending upon the wood being used, the same drill bit may produce different-size holes, especially when drilling into end grain as opposed to face grain. Choose a drill-bit size by experimenting with scrap stock, boring holes in both face and end grain. If there’s a variance, make sure the dowels fit well in the larger of the holes. The dowels can be sized with a file to fit into the tighter holes. Letter drill bits have sizes slightly larger and smaller than fractional sizes, affording better fits. In a pinch, I have reduced the size of stock bits with an oilstone while running the bit on the drill press.

The doweling jig itself

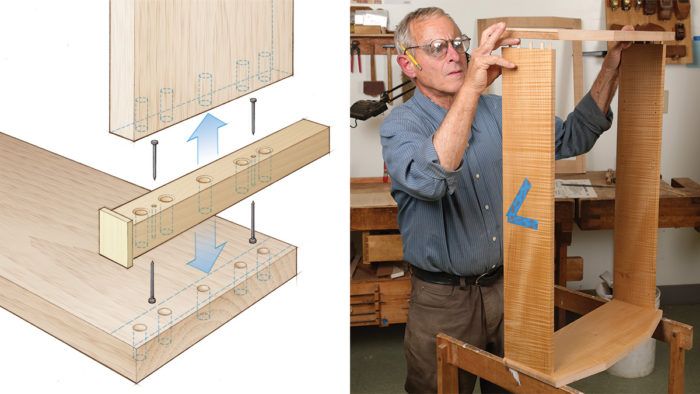

A doweling jig is a drill guide that is used to repeat the same hole pattern in joining parts. One end and one side of the jig serve as reference points. Understanding the relationship of the jig to each side of the joint can be confusing at first. Think of the jig as being sandwiched between the two parts of a joint. Dowel holes will be drilled from each direction through the jig to create one joint. The nails that locate the jig will be driven through one side of the jig for half of each joint and through the other side for the other half.

When making the jig, choose a width that is greater than the thickness of the carcase stock. That makes the jig’s reference edge readily evident because the holes will be closer to one edge than the other. Visual clues such as this can go a long way in avoiding confusion. A bandsawn non-reference edge serves the same purpose.

Glue a plywood heel on one end of the jig. It will serve as a fence to align the back edges of the two workpieces being joined. Keep the heel short, protruding no more than 1/4 in. beyond the face of the jig. A heel that’s too long may amplify a small variance.

To view the entire article, please click the View PDF button below.

|

|

|

|

|

Comments

Where is the pdf file? The link is not working.

Please check the link, still not working, many thanks.

Please check the PDF link - it is still not working.

Probably won't be available until issue #287 comes out in February...?

The link has been fixed.

Apologies all. This was scheduled to post while I was on vacation and missed the messages upon my return.

Log in or create an account to post a comment.

Sign up Log in