Gouges for the Lathe

Selecting and sharpening spindle, bowl and roughing-out gouges

Synopsis: Ernie Conover has noticed that anyone who learns how to handle a gouge with aplomb will be far along the road to mastering turning itself. There are three types of gouges: roughing-out, bowl, and spindle. Conover says the best gouges are made of high-speed steel, and he discusses tools you need for sharpening and how to hone the edges. Three side explanations detail the three categories of gouges and talks about what they’re used for, what they look like, and what Conover looks for when evaluating one.

I ‘ll never forget King Heiple, the orthopedic surgeon who signed up for one of my turning classes a few years ago. When I called the class to gather round as I demonstrated a new technique, he was the student who was right by my side, carefully studying my every move, Then he would go over to his lathe and do what I did, except he did it better. Not many of us are blessed with the ability to master a new skill so quickly. But I have noticed that anyone who learns how to handle a gouge with aplomb will be far along the road to mastering turning itself.

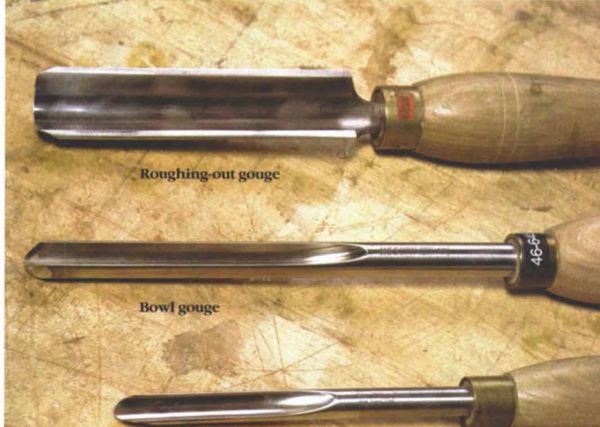

Gouges can be divided into three categories: roughing-out, bowl and spindle. When viewed in cross section, all are U-shaped, but their similarities end there.

Roughing-out gouges are the biggest of the bunch. They’re used to make square stock round. Spindle gouges have the shallowest flutes. They’re used for finely shaping the details on legs or posts. Bowl gouges have the deepest flutes and are employed when shaping vessels in faceplate turning.

Knowing a little about how gouges are made and what they’re used for can help in deciding which types you need to add to your turning arsenal.

You’ll need some tools and jigs to reshape and sharpen the gouges. Even premium tools leave the factory with a grind that’s only a caricature of the proper shape. That problem has plagued turners for more than a century. J. Lukin wrote of spindle gouges in his book, The Lathe & Its Uses, published in 1868: “When purchased, they require grinding, the bevel being too short. It is essential that this tool have a long bevel. It is impossible to do good work with the standard form of the tool which is, nevertheless, of frequent occurrence in the workshops of amateurs.”

The best gouges are made of high-speed steel

Gouges were first manufactured by forging and many are still made that way. High carbon steel is heated and hammered to the correct shape while hot. Premium gouges, made of high-speed steel, are machined into the proper shapes.

From Fine Woodworking #123

For the full article, download the PDF below:

Log in or create an account to post a comment.

Sign up Log in