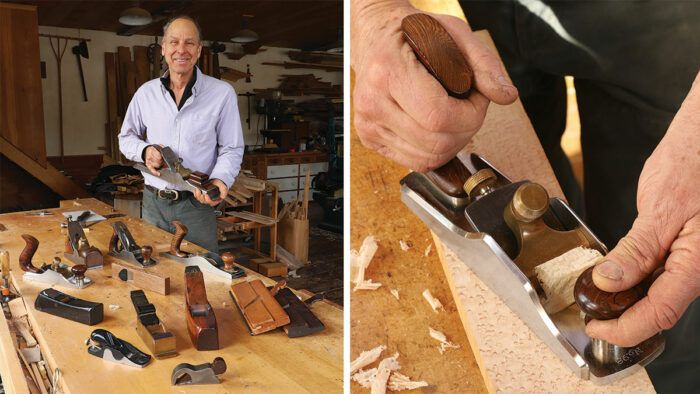

Garrett Hack’s favorite hand planes

One thing Garrett has learned over the years is that you don't need a lot of planes, just good ones. Here, he shares the stories of some of his favorites.

Synopsis: It’s safe to say that Garrett Hack is pretty fond of hand planes. He has traveled to Europe and Japan and all over North America to teach about them, he has been collecting them for years, and he’s a master at using them. One thing he’s learned over the years is that you don’t need a lot of planes, just good ones. Here, he shares the stories of some of his favorites.

I’ve been drawn to tools since I was 3. I have photos to prove it: Me, sawing on the rungs of my high chair and driving a nail into the seat to repair it. Who knew where this fascination with hand tools would lead, that every day I would get to enjoy using beautiful planes to build things. Some I prize for the way they work—dependable and efficient—and others for their gorgeous materials, their patina, and their soul. Each has a story.

My first planes were always users—affordable and needing a lot of love to overcome a hard life. Flattening and sharpening those third-hand tools taught me how to make planes work and which ones could really be revived. Some didn’t work well and got passed on, teaching me what to avoid next time. In the end I found that you don’t need a lot of planes, just good ones. I’ve collected some of my favorites here.

The Stanley heritage

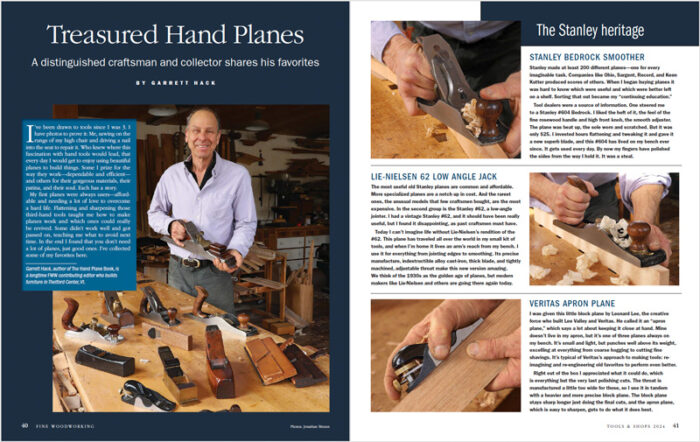

Stanley bedrock smoother

Stanley made at least 200 different planes—one for every imaginable task. Companies like Ohio, Sargent, Record, and Keen Kutter produced scores of others. When I began buying planes it was hard to know which were useful and which were better left on a shelf. Sorting that out became my “continuing education.”

Tool dealers were a source of information. One steered me to a Stanley #604 Bedrock. I liked the heft of it, the feel of the fine rosewood handle and high front knob, the smooth adjuster. The plane was beat up, the sole worn and scratched. But it was only $25. I invested hours flattening and tweaking it and gave it a new superb blade, and this #604 has lived on my bench ever since. It gets used every day. By now my fingers have polished the sides from the way I hold it. It was a steal.

Lie-Nielsen 62 low angle jack

The most useful old Stanley planes are common and affordable. More specialized planes are a notch up in cost. And the rarest ones, the unusual models that few craftsmen bought, are the most expensive. In the second group is the Stanley #62, a low-angle jointer. I had a vintage Stanley #62, and it should have been really useful, but I found it disappointing, as past craftsmen must have.

Today I can’t imagine life without Lie-Nielsen’s rendition of the #62. This plane has traveled all over the world in my small kit of tools, and when I’m home it lives an arm’s reach from my bench. I use it for everything from jointing edges to smoothing. Its precise manufacture, indestructible alloy cast-iron, thick blade, and tightly machined, adjustable throat make this new version amazing. We think of the 1930s as the golden age of planes, but modern makers like Lie-Nielsen and others are going there again today.

Veritas apron plane

I was given this little block plane by Leonard Lee, the creative force who built Lee Valley and Veritas. He called it an “apron plane,” which says a lot about keeping it close at hand. Mine doesn’t live in my apron, but it’s one of three planes always on my bench. It’s small and light, but punches well above its weight, excelling at everything from coarse hogging to cutting fine shavings. It’s typical of Veritas’s approach to making tools: re-imagining and re-engineering old favorites to perform even better.

Right out of the box I appreciated what it could do, which is everything but the very last polishing cuts. The throat is manufactured a little too wide for those, so I use it in tandem with a heavier and more precise block plane. The block plane stays sharp longer just doing the final cuts, and the apron plane, which is easy to sharpen, gets to do what it does best.

The English infills

Norris A6

I first read about Norris planes in Fine Woodworking, and learned that these legendary planes performed like no other with their heavy dovetailed steel bodies infilled with dense rosewood and their thick blades. I looked for one for years. I often went to a county auction and flea market in New Hampshire that had lots of users of every type mixed in with rare tools, rusted junk, and bushel baskets of molding planes. One year I came upon a dealer’s table that held three Norris planes and nothing else.

Of the three, the only one I remember was a square-bodied smoother in stunning condition—dark rosewood, beautifully shaped handle, a blade adjuster, and a daunting price. I bought it, and have come to learn that my A6 is rare and one of the best ever made. And you know, I don’t recollect the exact price, but I certainly remember the years of pleasure and exceptional work it has given me.

Spiers Jointer

A small Scottish company, Spiers was a competitor of Norris, a bit earlier, and a notch above in quality. I came across this Spiers jointer plane at a premier tool auction in England run by David Stanley. At the auction preview I looked at lots of planes, but I focused on this one, with its fine sculptural handle, rich rosewood, nearly full blade, and unusual length. The auction was held in a ballroom in a country motel where within a few hours 800 or more lots of planes, saws, chisels and who-knows-what were sold. The action was lightning fast, under 15 seconds per lot, and the room had the energy of the New York Stock Exchange—packed, frenetic—and was fueled by a busy bar at the back of the hall. That was where I found myself standing as the bidding started on lot #Q. Just then two burly men pushed in front of me, and all I could do was jump high and wildly flash my bid card over their heads. To my surprise, it worked, and the plane came home with me.

Owners often stamp their names on their tools, but one James Bond, who owned this Spiers jointer sometime before me, a little too enthusiastically stamped his name seven times. Did you say 007?

British custom planes

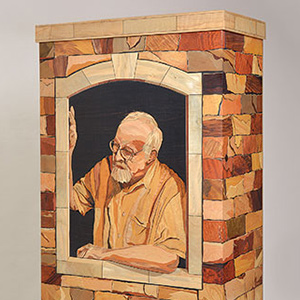

Bill Carter’s thumb

Some planes are double gifts—when a wonderful tool comes with a friendship. I met planemaker Bill Carter in Leicester, England, when researching my first book. In his little unheated garden shed Bill was sawing and filing bronze from electrical salvage, brass backs from tenon saws, boxwood from local hedges, and new blades from old blades. He makes gems with deep soul that look 100 years old and are highly precise. In a play on Norris’s practice, he stamps his planes similarly: “Carter, London.”

When he wanted a cabinet to show off some of his best planes, we arranged a trade. A year later we met up at The Festival of the Tree in the National Arboretum—a wild collection of every kind of woodworking. Out of Bill’s coat pocket comes this bronze thumb plane. When I calmed down, I tapped out the ebony wedge to see the blade and how my plane was built. The wedge felt just a tad tight; being cocky, I told Bill I might have to take a shaving off it when I got home. He said he would come “whup” me if I did. He hasn’t had to.

Karl Holtey smoother

Karl Holtey makes precise infill and other planes that work incredibly well. Some are modeled on classic Norrises, others are his own design. He is meticulous about construction, from fine depth adjusters to space-age steels for blades. We became friends when I bought a couple of planes to test drive and give him feedback.

My #98 is a Holtey original design, a low-angle smoother in stainless steel, rosewood, bronze, and high-tech blade steel. With any new plane I expect it could take a year or more to fully understand and get the best work from it, so I always put in the time. For weeks this one frustrated me. The blade is marked “E”—for Extra ornery, I came to think, as my diamond stones could barely sharpen it. Karl sent me a new blade, but it wasn’t any more friendly. In the end, Ron Hock made me a simple high-carbon blade that works like a dream. Just like the plane.

User-made planes

Bullnose Rabbet plane

In Colchester, Conn., in 1827 Hazard Knowles cast the first iron bench planes, heavy and clunky versions of what we use today. Lots of inventors and companies followed his lead, exploiting a material with obvious advantages of durability, precision, and low-cost mass production. It’s what led to Stanley Tools dominating the world plane market.

Since many factories had foundries, workers sometimes experimented with casting their own planes. This is the origin of my rough bullnose rabbet, which was made in a single casting instead of having steel plates dovetailed together and infilled with rosewood. The plane took lots of tuning and I spent years learning its abilities. It’s too light for hard work but ideal for chamfering around the inside of a drawer or the frame around a panel. It’s indispensable for this, but I have to be careful lest that rabbet blade veer off and gouge my work.

Coopering plane

Wooden planes, which looked neat and were inexpensive, were the first ones I bought. They were usually worn, had poor blades rusted from years of idleness, and they never worked consistently. At a Maine flea market, I found this narrow, torpedo-shaped plane made from dense dark wood with a top-quality cast steel blade. It felt warm and comfortable in my hand. A boatbuilder, I found out, had fashioned it from lignum vitae—an unusual wood for planes but one found around boatyards—to be used one-handed in tight spaces on a hull.

To restore it, I chopped out a section of the sole ahead of the throat and inlaid a piece of rosewood. At first I used it as a long block plane. Then, when I was trying to smooth the inside of a curved door, I reshaped the sole to a slight arc, and it became a coopering plane. It’s how I have used it since, which is natural considering its history.

Ebony Krenov-Style Plane

Furniture making seems like a romantic career, but in truth it’s tough. Since I am well past the early struggle phase, I’ve been mentoring emerging makers, giving them advice and sometimes tough-love feedback. A young maker gifted me this sleek plane just because he appreciated my visiting his shop to see what he was building. I’ve grown to love it as a tool and for what it means.

The maker grew up near The College of the Redwoods, the school Krenov made famous, where this way of building planes is in the air. It has the usual short Hock blade (wonderful high-carbon steel), a body shaped to fit the maker’s hand (and mine too), and tool marks carved into the heel that make it personal and easier to hold. That it’s made of rich ebony, a favorite wood of mine, makes it even more appealing. It’s not a tool for finish cuts—the throat is too wide for that—but it can work hard with almost frictionless ease.

Molding and kanna

Molding planes

Some of the first well-paid woodworking I did was producing specialty moldings—making new runs and, more challenging, matching existing profiles. Shaper and router cutters were fast, but limited; with the right molding planes, though, I could make almost anything. Every flea market had boxes of antique planes—a bonanza; I quickly learned to avoid ones badly worn, warped, or with rusted blades.

I bought the most useful shapes—hollows and rounds (which cut what their names suggest), and over time assembled this group of graduated bead planes. They didn’t all start out the size they are today. I discovered some were too worn to work well or were less useful sizes, so I restored the ones I could and sawed off the sole of others, added a new sole, and re-shaped it. The blades took time to reshape and sharpen, but that’s typical of molding-plane blades. I even improved on the originals by adding a tough tropical wood fence.

Japanese smoother

Twice I was invited to Japan to teach about design and western hand planes; I probably learned more from being there than my students did from me. Japanese woodworkers have a very long tradition of wooden planes fitted with thick forged blades, with not a lot of variety and almost always of durable white oak. My little plane is red oak and is as pared down as a plane can be—just two parts: blade and body. It’s the user’s responsibility to fit the tapered blade to tapered slots in the sides of the body so the blade is tight and a good working depth at the same moment.

Japanese planes have always had a mystique, requiring special tuning of the sole and natural stones for sharpening. Wooden planes do need constant attention, which is why my students there had so much interest in consistent western iron planes. While I was there I met a craftsman considered a national treasure who makes just plane bodies. And I learned there are many paths with Japanese planes; now they seem less mysterious, and I remember Japan when I use my little plane.

—Garrett Hack, author of The Hand Plane Book, is a longtime FWW contributing editor who builds furniture in Thetford Center, Vt.

Photos: Jonathan Binzen.

To view the whole PDF, click on the “View PDF” button below:

Log in or create an account to post a comment.

Sign up Log in