Cutting side beads

Bill Pavlak provides four hand-tool approaches to classic molding.

For a simple and effective way to enliven an edge, cabinetmakers have long turned to the humble bead. This rounded-over edge, set apart from the adjacent flat surface by a quirk—a deep, narrow channel—adds an elegant interplay of shadow and light along the edges of things like straight table and chair legs, face frames, drawer fronts, and lapped backboards. There are many ways to sink a side bead into a board with hand tools that range from very expensive to super cheap. Here’s a look at four of them.

Screw Stock

Among the least expensive and most clever tools in existence, the screw stock is simply a slotted wood screw protruding a desired distance from a scrap of wood. That’s it. Use a mill file to flatten the head of the screw and create a sharp edge at either end of the slot. Take care to keep the fence (block of wood) tight against your workpiece and then push and pull the tool to scratch a little bead. You may have to play with your angle of attack to engage the screw slot so it’s making shavings like in the photo below.

The screw stock’s virtues (micro-adjustability and cost) are offset by the fact that you only get half of a bead: The slot cuts the quirk while the underside of the screw head compresses the wood to form the inner half of a bead. Sometimes I find that the shadows that gather in the quirk add enough visual interest that a full bead is not necessary. Often enough, I’ll use a file or block plane to quickly round over the outer edge. Shallow beads can also be worked along curves by using a curved block of wood as the holder.

Scratch Stock

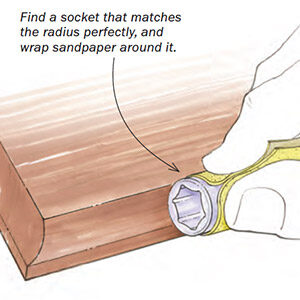

A screw stock is probably the only tool that could make a basic scratch stock seem pricey. Small beads with nice full profiles are easy to make with a scratch stock on straight and curved edges alike. You make the cutter by using a round file on scraps of steel harvested from things like cabinet scrapers or old sawblades. It will cut cleanest if the curved edge and both faces are polished on fine sharpening stones or sandpaper. The finished blade can be held in a scrap of wood with a sawn slot and a screw or two—a couple of options are shown below.

In use, start with a few light passes making certain the fence is snug against the workpiece. Once again, experiment with the angle the blade engages the wood to get the best results. Scratch stocks are versatile and can be made to drop a bead in the middle of a board or on a rounded column as easily as along the edge. If they have a downside, it’s their tendency—like with most scraping tools—to struggle in softer woods.

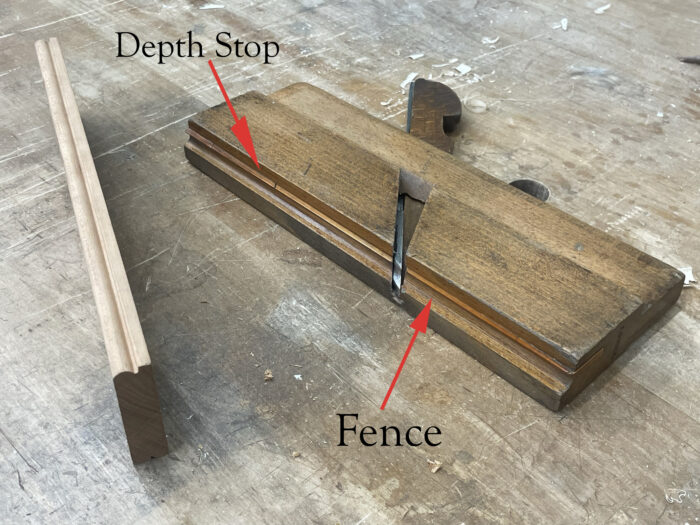

Side Bead Plane

Side bead planes are designed to do one thing in one size only. Want a different size bead? Buy another plane. That said, they do their job very well and with great efficiency. The beauty of molding planes like this lies in their combination of a well-supported blade (this leads to cleaner cuts) and two user-friendly features. Namely, they have a built-in fence and depth stop that ensure consistency and ease of use.

The first drawback of beading planes is obvious: it can be expensive to buy one let alone a whole stable of them. New planes from top makers will cost $250 or more, though user-grade antiques can be found for a fraction of that cost. While side beads are some of the easiest molding planes to use, they are among the fussiest to sharpen and maintain. Keeping that small, tightly curved blade sharp while maintaining its shape requires great care. Still, they’re a treat to use, and it’s hard to argue with the results.

Combination Planes

Combination planes can be among the most expensive tools on both the new and antique tool markets. That cost is potentially easier to swallow when you consider the tool’s versatility – grooves, rabbets, beads, flutes, etc. While this jack-of-all-planes does not do everything well (I’m looking at you, cross-grain work), it excels at things like beads. The narrower beads preferred for furniture (1/8 in. to 3/8 in.) receive enough support from the plane’s adjustable bed for smooth cuts. The adjustable fences and depth-stops allow it to be used along an edge or farther in on a workpiece with consistent results.

Log in or create an account to post a comment.

Sign up Log in