Chairmaker’s Planes

On overview of the specialty planes that chairmakers have used for centuries.

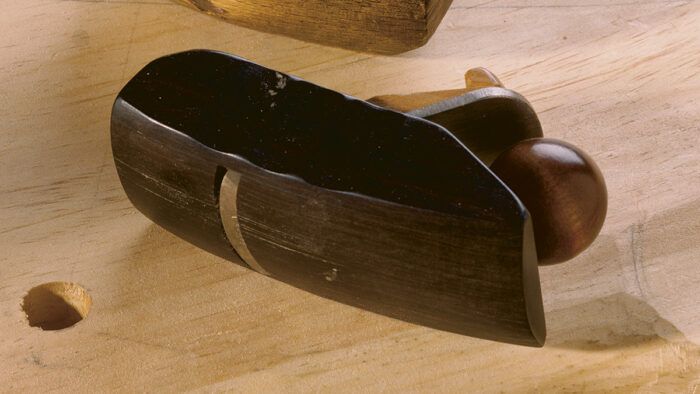

Chairmakers hollow plank seats with larger versions of finger planes, with the same doubly compassed soles. Many of these planes are either craftsman-made or modified to work a particularly favored seat shape, from deeply hollowed to one more shallow. Just as useful are large shaves, often called travishers, with strongly radiused irons and handles curving away from the work to keep the user’s knuckles out of harm’s way. As with the planes, a chairmaker needs a number of travisher shapes to fit specific seat shapes.

To shape a seat, chairmakers start with a thick plank (usually white pine or basswood) cut roughly to shape. They hollow the center and shape the edges with shaves and planes, leaving a shape that’s both comfortable and practical. The hollow is deeper toward the back to give the sitter a slight backward cant, and it’s left thickest where strength is needed to joint in legs, spindles, and rails.

Chairmakers have adapted one other plane to their needs: a scraping spokeshave known as a devil. It’s used to shape and smooth spindles and the “bows” for rails and arms. With a short sole shaped to fit the circumference of the part and a bone or brass insert ahead of the blade to counter wear, it’s the most practical tool for smoothing curved parts. A devil can follow complex shapes, such as the continuous back rail on some Windsor chairs—a task nearly impossible with other planes.

Excerpted from The Handplane Book (The Taunton Press, 1999) by Garrett Hack.

Excerpted from The Handplane Book (The Taunton Press, 1999) by Garrett Hack.

Available at Amazon.com.

Log in or create an account to post a comment.

Sign up Log in