All About Industrial Machinery

Shapers and combination machines, to name a few, are powerful woodworking tools more commonly found in professional and production woodshops.

The Basics:

• Shapers: A powerful alternative to the router table.

• Combination machines: Five functions wrapped up in one.

• Specialty tools: From edge-banders to molders, some equipment is strictly for the pros.

Shapers

Variable-speed routers and the proliferation of router bits available to woodworkers have eliminated the need for a shaper in many woodshops. But these are relatively new advancements in woodworking technology. For some time, large jobs creating molding or complex edge profiles were done exclusively with a shaper. This powerful tool, which operates almost exactly like a router table, is capable of cutting in one pass moldings that would take several passes to produce with a router. Its size and weight also nearly eliminates vibration, allowing a shaper to produce a flawless surface on the toughest of woods.

Shaper knives, which typically consist of three profiled cutters mounted to a spindle, are available in a limited number of profiles. However, custom cutters are easy to come by. Most cutter manufacturers offer services to produce cutters to specifications. Alternatively, the knives can be sharpened by hand with the right equipment and skills.

Combination machines

Popular in Europe but not so common in the U.S., combination machines typically combine the features of the tablesaw, sliding tablesaw, shaper, jointer, planer, and horizontal mortiser in a single unit. In addition to having multiple functions, combination machines also feature multiple motors.

With a price tag from $6,000 to as much as $20,000 depending on features, and an average weight of about 1,500 lb., it’s no wonder that most home hobbyists don’t choose a combination machine over multiple single-purpose tools. Even if one could justify the investment, combination machines don’t have the portability that most home shops require.

Specialty equipment

In a custom woodworking shop or production furniture shop, you will find a number of woodworking machines that you likely won’t find in a home shop. That’s because many industrial-grade woodworking tools require a big investment as well as heavy use to make the investment worthwhile.

Shops that deal with laminate and sheet goods may employ a high-priced edge-banding machine, which automatically applies glue and edge tape to a workpiece. Shops that produce large quantities of elaborate window trim or crown molding may find it more economical to use an industrial-grade molder than alternative methods. Machines designed to drill holes for European hinges are further examples of industrial machinery common to professional and production shops.

In a class above these industrial-grade tools are CNC (computer numerical control) machines, which are programmed with computer software to make a series of cuts. These machines can be designed to accommodate a number of operations including lathe work and routing.

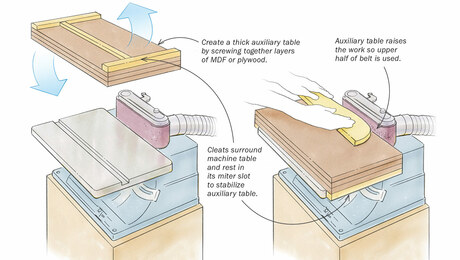

Wide belt sanders, commonly referred to as a “timesaver” after the popular manufacturer of these tools, and horizontal boring machines, might be considered entry-level industrial tools, as they can offer a great deal of efficiency for a small professional shop.

Log in or create an account to post a comment.

Sign up Log in