All About Butt Joints

The butt joint is the simplest way to join two pieces of wood, forming a seam along the grain. This joint is not used to increase the length of a board, but to increase the overall width of a panel.

The Basics:

• A simple way to join edges: Make large panels from narrow boards.

• Anatomy of the joint: Straight edges and a little glue is all that’s required.

A simple way to join edges

Any project that requires a panel or surface wider than the available material can employ the butt joint. By joining two boards along the edge, the woodworker can take advantage of natural grain patterns to enhance the design. Another application might be the strengthening or thickening of a member, such as a stile or rail.

The butt joint is not a wise solution for joining two ends, or an end to an edge, unless you add additional reinforcement, such as dowels or biscuits. This is mainly because end grain will not make a tight bond.

Anatomy of the joint

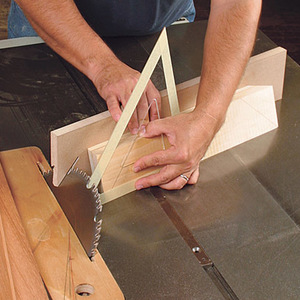

The strength of the joint relies on the straightness of the edge (not necessarily the squareness) and the orientation of the wood fibers. This joint doesn’t require any special machining of parts. The only preparation is the planing or jointing of the edges for straightness.

With modern adhesives, this joint can be as strong as the wood itself. One advantage of the butt joint is speed. However, without a means to register two edges for a flat seam, you’re generally restricted to joining lengths not exceeding 48 inches. Any longer, and aligning the pieces becomes difficult.

Log in or create an account to post a comment.

Sign up Log in