Add Muscle To Your Miters

Shopmade L-shaped tenons create a powerful joint

Synopsis: Miter joints are perfect for seamless joinery, such as when you want long grain to flow around a door frame, the edge of a case piece, or from leg to rail in a chair. The joint is also great for sheet goods because it hides the inner layers. But the glue surface in the joint is mediocre, and there isn’t much space to reinforce the joint to make it stronger. L-tenons, shopmade right-angle slip tenons that allow you to sink a long leg into each side of a miter joint and add plenty of glue surface, are a clever solution. Here, three furniture makers who use this joint often share their L-tenon know-how.

For those who like their joinery subtle and seamless, the miter is indispensable. It allows long grain to flow around a door frame, over the edge of a case piece, or from leg to rail in a chair, unbroken by end grain. and it lets you join sheet goods without exposing the inner layers.

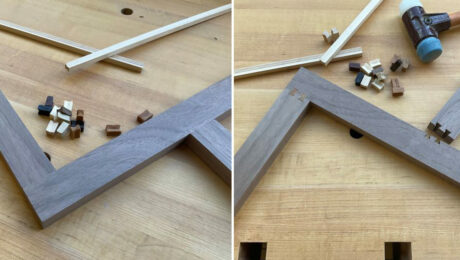

But the miter’s glue surface—especially in solid wood—is mediocre, and the space for reinforcement, whether with biscuits, slip tenons, or splines, is limited and also compromised in terms of glue surface. For some years now, we’ve been seeing a clever solution used by a number of craftsmen: L-tenons, shopmade right-angle slip tenons that allow you to sink a long leg with plenty of face-grain glue surface into each member of a miter joint. L-tenons can be used with almost any sort of miter and on any scale.

We’ve brought together three fine makers who use the joint frequently, each taking a different approach but all ending up with what one calls “an indestructible miter joint.”

Three versions of the L-tenon

Reinforcing miter joints with L-shaped tenons makes a beautiful joint suddenly much stronger. The tenons’ 90° turn produces a joint with much more available glue surface, all of it face-grain. It also can make for simpler assembly.

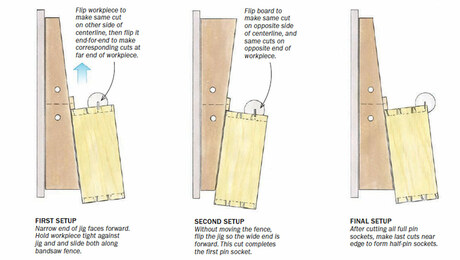

Finger-jointed L-tenons

Solid-wood cases with mitered corners are at the heart of my furniture making. Most of my pieces involve carving, and in pursuit of good surfaces to carve, I build wall cabinets, freestanding case pieces, and small boxes, most of them mitered. And on all of those miters I use L-tenons made by finger-jointing two pieces of solid wood. Yes, I spend a fair amount of time making the tenons, but the resulting strength of the joint is well worth it. Using this technique, I’ve made L-tenons in sizes ranging from 3 in. across for large case pieces to barely 3⁄4 in. for small boxes. The L-tenon miter joint allows for more straightforward assembly than typical splined miter joints, which must be assembled on the diagonal, often causing a bit of juggling in the glue-up.

For the full article, download the PDF below:

Log in or create an account to post a comment.

Sign up Log in