17 Tools Every Woodworker Should Have

From the humble card scraper to a pair of handy folding horses and a shopmade router table, here's a list of items in Charles Durfee's shop that he swears by

When we hang out with fellow woodworkers—whether online, in print, or in person—shop talk usually gravitates toward new twists on machinery, tools and techniques, and what we’re making at the moment. It’s all useful information, of course, and fun to talk about. But in the past few years, in the past few years, I’ve been having an internal discussion, noting the items in my shop that, over decades of use, I’ve really come to rely on and to appreciate, even if they may fly under the radar of shop-talk circles. Running the gamut from tweezers to my old workbench, these items range from the humble, perhaps hiding on a shelf and only occasionally used, to the more prominent and frequently used. But they all make my private pantheon.

1. My workbench

The absolute heart of my shop. I use it for joinery, shaping and surfacing, checking for flat, assembly, and of course for leaning on. Based on traditional German cabinetmaking benches, it’s solid and heavy but can be moved in a pinch. I use it from both sides. Because I’m left-handed, I built it with the face vise on the right and tail vise on the left.

2. Card scraper

The card scraper is probably the most cost-effective tool in my entire shop. With this simple piece of quality steel (mine is Sandvik), I can clean off a surface, leaving it only in need of light sanding. It’s also great for getting at particular spots that need attention, without affecting the surrounding surface. Saves a lot of sanding!

3. Cabinet Scraper

I found using the Stanley #80 cabinet scraper frustrating at first. But after it’s properly tuned up and sharpened this is a great tool for taking off wood, and it’s especially useful when the board has a lot of figure. It’s more aggressive than the card scraper, and the two work well in tandem.

4. Nicholson #50 Rasp

The Nicholson #50 rasp is a veteran of the patternmaking trade. It takes wood off in a hurry, but it doesn’t leave grooved scratches.

5. Glardon Vallorbe Detail File

The Glardon Vallorbe detail file has round and flat surfaces, both coarse and fine, so it offers lots of choices in one tool.

6. Lie-Nielsen Block Plane

This block plane is just as sweet a small plane as you will see. It has a heavy cast iron body and it took a bit of time getting used to the weight, but now I wouldn’t have it any other way. It’s a pleasure to adjust and to work with.

7. Understanding Wood Finishing by Bob Flexner

Finishing can seem like voodoo science, but Understanding Wood Finishing by Bob Flexner goes a long way toward demystifying it. It’s been my bible in the times when finishing tries my soul, which occur not infrequently.

8. Bessey Bar Clamps

I have pipe clamps and steel I-beam bar clamps, but they gather dust in the corner. I was exposed to these Bessey bar clamps while teaching at the Center for Furniture Craftsmanship more than 20 years ago and became a convert, gradually building up my own set. They are light, don’t mar the work, sit upright on the bench, and their heads stay parallel and square so panels won’t buckle. The newer ones have a nice rubber handle.

9. Pneumatic Drum Sander

This pneumatic drum sander chucks in the lathe and can be inflated to soft or firm. It’s perfect for sanding curves of all sorts, and you can sand flat stock on it as well.

10. Splinter Pullers

Splinter are as humble as can be, but when I need them—and invariably I do—I’m delighted to have them. Mine have little micro points that curl slightly inward at the tip and are very effective. I got this pair, called Splinter Picker, from my local hardware store many moons ago. Lee Valley sells similar ones. Anyone who works with roughsawn wood will know why they’re so valuable!

11. 1⁄4-in.-Thick MDF

1⁄4-in.-thick MDF is about as humble as one can get in the woodshop, but I find it invaluable for making patterns. It is easy to cut and shape, and holds up through multiple uses.

12. Tenon Cutters

Using tenon cutters is vastly easier and more accurate than sizing tenons on the lathe with turning tools and calipers or an open-ended wrench. You can use a tenon cutter on the lathe or chuck it in the drill press. With the latter, I use a clamping jig to hold the workpiece.

13. Flush-Trimming Router Bits

My favorite flush-trimming router bits are the type with both top and bottom bearings. They’re great for pattern shaping. Add some double-sided tape to hold the workpiece to the pattern, and they remove all the anxiety over situations where you would need to cut against the grain.

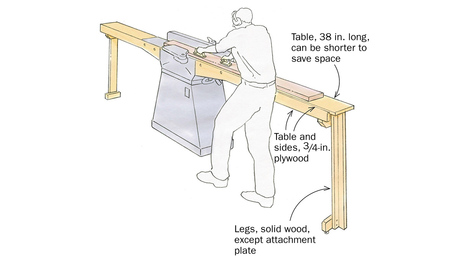

14. Shopmade Router Table

This shopmade router table doesn’t have much in the way of snazzy micro adjusters, but it works well with plenty of accuracy. It has a nice large work surface, dust collection, and a hefty 3-1⁄4-hp Porter-Cable router to drive the cutters.

15. Squaring Sticks

I’ve made a few pairs of these squaring sticks in different sizes. The two sticks mate—and slide—with a tongue-and-groove along their length; a wingnut locks in the measurement. Used for taking inside diagonal measurements to check for square during the assembly process, they’re more accurate and mistake-free than a tape measure.

16. Power Cord Reel

A power cord reel is very handy. I don’t like stuff underfoot, especially power cords. If you plug a cord into a wall socket and then are working on something in the middle of the shop … well, you know what I mean.

17. Folding horses

In almost any shop, versatility in the use of space is important. My main machines are fixed in place, but the remaining open floor space is used for lots of things. I often take advantage of it with my pair of folding horses. I pull them out for sorting rough stock or gluing up large panels. If I add a sheet of 3 ⁄4 -in. MDF I’ve got an assembly or finishing table. Put them away when you need the space for something else. Super useful in a small shop!

From Fine Woodworking #272

Comments

Good advice all around.

Well written and informative--Articles like these are very useful to beginners who are trying to figure out what tools they need.

Good job!

,Well, I'll try this again; it disappeared once. Each of Mr. Durfee's advice is invaluable to those of who are improving our work and our shops. Thanks!

I would add a couple of items in addition to the tweezers:

First, a product called "Wound Seal" for quickly stopping bleeding. If you're like me, cuts are routine. This comes as a powder in 4 small tubes; it is sprinkled on a cut and forms a clot instantly. Find it at the local pharmacy.

There is another brand out there but I don't recall the name. I recall something like this developed during Vietnam.

Second, eye wash. Getting a bit of sawdust in the eye is inevitable; getting it out quickly is important. A small bottle of eye wash is a great thing to have immediately available.

Log in or create an account to post a comment.

Sign up Log in